The waste heat recovery technology has been tested by these five different prototypes with different variations in power electronics, thermal collector contact surfaces, cooling system and the thermoelectric generators to configure the best option for each type of heat source.

Efficiency is one of the main parameters analysed in each project. This parameter shows how much energy is extracted from waste heat.

The efficiency of the prototype depends on the heat source, the heat collector type and the cooling system applied.

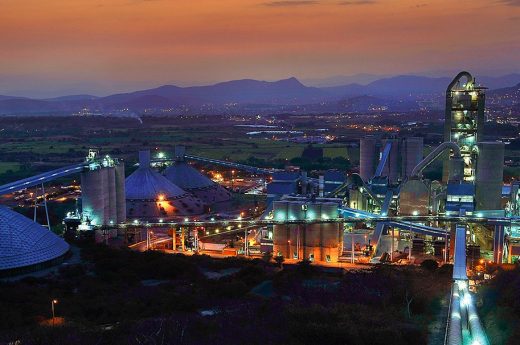

The activity of Ciments Molins Group focuses on manufacturing, distributing and selling cement, concrete, mortars, aggregates and concrete prefabricates, and running activities and production plants in different countries.

The energy recovery system (Heat R-System) installed in the industrial plant that Ciments Molins has in St. Vicenç dels Horts (Barcelona) makes use of the waste heat generated in the walls of the rotatory kiln used for firing the clinker and which are close to the burner.

The operating cycle of the rotatory kiln is 24 hours a day, 7 days a week, and the heat source temperature is about 200 ºC although the temperature inside the rotatory kiln is up to 1000ºC. The device must withstand ambient temperatures up to 40 ºC.

The recovery system obtains heat by conduction and is non-intrusive.

The forced air generated by fans cools the equipment to obtain the maximum temperature difference between the two sides of the Peltier cells.

In this project, the energy recovery system is based on a new type of WHRU:

WHRU – HSCD100

- Cooling system principle: Forced air convention

- Cooling components Heat sink with four fans.

- Heat capture system principle Conduction

- Thermal collector Plane thermal collector.

- Electrical energy generator Thermoelectric generator TEG – Peltier cell

- Peltier cell number 36 cells 40 *40 mm

The main feature of this device is that it groups a set of 36 thermoelectric generators into a single unit. This design was created to group as many thermoelectric generators as possible in the smallest possible space, optimising the ratio of power generated per unit area.

Results

| Heat source temperature | 191 – 213 ºC |

| Generation area WHRU | 1705.7 cm2 |

| Mean power generated | 5.43 W |

| Maximum power generated | 6.86 W |

| Energy generated | 47.6 kWh/year |

| Power density | 31.83 W/m2 |

| Heat dissipated by the square heat source | 310 W |

| Heat flow through Heat R-System by conduction | 491 W |

| Efficiency | 1.40 % |

Prototypes based on a forced air-cooling system with a heat collector in contact with a hot surface have been found to be the least effective and efficient.

To generate more energy, it is necessary to capture the maximum amount of heat flow. This is possible if the system is intrusive and there is contact between the fins of the heat collector and the hot gases. At Ciments Molins, the system is non-intrusive and the heat is obtained by surface contact between the heat collector and the hot wall of the rotary kiln.

On the other hand, there is a higher heat transfer due to the higher number of Peltier cells mounted.

Unlike the forced water-cooling system, the forced air-cooling system cannot absorb all the heat. This means that there is no temperature difference between the sides of the Peltier cells and the efficiency is lower.