LIFE - HEAT-R

WelcomeThe installation was carried out on February 20, 2020.

The conduit was manipulated by the maintenance staff of Gomà Camps following the instructions of the mechanical department of AEInnova.

The final installation of the recovery system was carried out jointly with the staff of AEInnova and Gomà Camps.

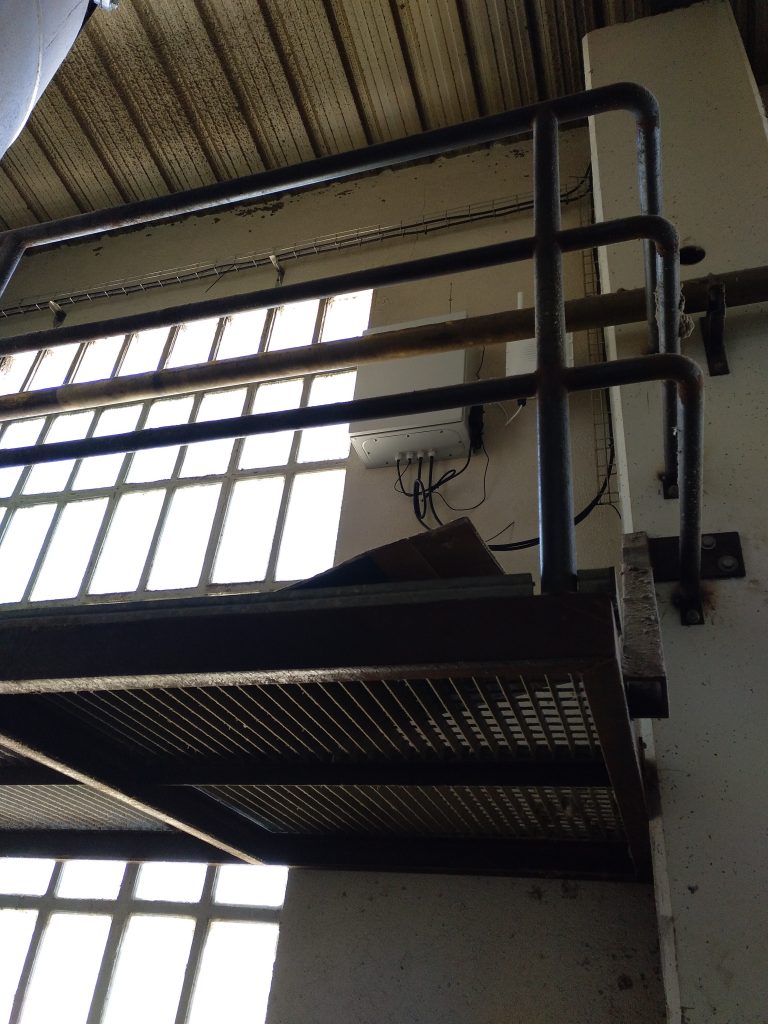

Below you can see some of the photographs taken at the installation.

In order to start a thermoelectricity project, it is important to have a physical visit to the facilities in order to determine the waste heat ranges and the temperature in addition to the installation of the WHRU system. The technical visit was made at the Gomà-Camps facility in La Riba (Tarragona) on July 9th, 2018.